Mission-Critical Manufacturing Capabilities: Advanced CNC Machining & Engineering Solutions

Brinkman Industrial & Defense delivers manufacturing capabilities with precision for the aerospace, defense, and industrial sectors, backed by full ITAR compliance and rigorous quality control. We specialize in producing complex components that perform in the harshest environments, ensuring absolute reliability for mission-critical applications where failure is not an option.

Combining state-of-the-art multi-axis CNC technology with deep metallurgical expertise, our facility is optimized for processing high-temperature superalloys, stainless steels, and exotic materials. From intricate prototyping to scalable production runs, we provide the advanced engineering and machining capabilities necessary to meet your most challenging specifications.

MACHINING SPECIALTIES

Brinkman Precision, Inc. delivers end-to-end aerospace manufacturing solutions, integrating advanced multi-axis CNC turning and 5-axis milling with specialized finishing processes. From SolidWorks engineering support to wire EDM, laser marking, and ultra-precision ID/OD grinding, we manage the entire production lifecycle. Our facility handles complex geometries and mission-critical features, including internal thread grinding and controlled atmosphere heat treating.

- Advanced Engineering Capabilities (Solid Works) & Support

- Ultra-Precision Grinding (ID, OD, Surface, Match Grinding)

- CNC Thread & Form Grinding

- Crush Form & Multi-Axis CNC Form Grinding

- CNC Match Grinding (embedded w/air gauging modules)

- Multi-Axis CNC Turning w/ Full Y-Axis

- EDM Wire, Electrode & Production CNC Drilling

- CNC Milling – High Accuracy – 4th/5th axis

- Precision Production Honing

- Laser Marking

- Vacuum & Controlled Atmosphere Heat Treating/Braze (including high Temperature Gold-Nickel)

- High Precision Metrology Equipment including CMM scanning and high accuracy roundness measuring

- Prototypes, Assembly and Testing

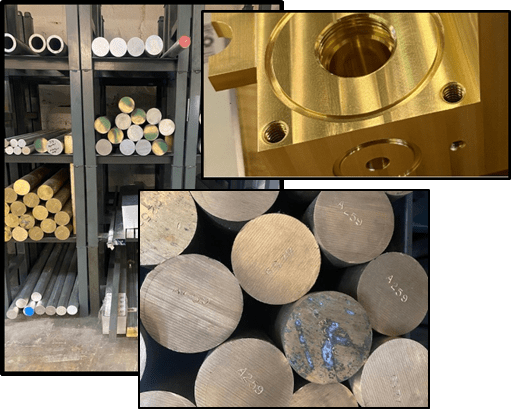

MATERIALS EXPERTISE

We possess specialized metallurgical expertise in machining high-temperature superalloys and exotic materials required for turbine and combustion applications. BPI is equipped to process hard-to-machine aircraft alloys such as Inconel, Hastelloy (HastX), and L605, as well as Titanium and hardened Tool Steels. Our tooling and processes are optimized to maintain material integrity while machining stainless steel, aluminum, and ductile irons.

- High Temperature Aircraft Alloys (such as L605, Inconel and HastX)

- Stainless Steel (All Types)

- Titanium

- Tool Steels

- Low, Medium & High Carbon Alloy Steels

- Aluminum, Brass & Bronze

- Cast / Ductile Irons

All Material Lots are Assigned a Lot ID for Traceability

TOLERANCES (GENERAL)

BPI achieves ultra-tight tolerances essential for aerospace fit and function, consistently holding specifications down to the millionths of an inch. We maintain ground external diameters to .0001” with roundness accuracy within 15 millionths, and match grind components to .000050”. Verified by high-precision CMM scanning and air gauging, our processes ensure repeatability for features requiring sub-micron accuracy.

- Turned Diameters +/- .0002

- Turned Lengths +/- .0004

- Ground External Diameters .0001 (15 millionths roundness)

- Ground Internal Diameters +/-.0001 (50 millionths roundness/straightness)

- Match Grind to .000050 to .0001

- Ground Shoulders +/- .0001

- Surface Grinding +/- .0001

- Milling Tolerances +/- .0002

SIZE CAPACITY (GENERAL)

Our facility offers versatile production capacity for a wide range of component scales, handling turned diameters up to 15-3/4” and milling envelopes up to 20” x 40” x 25”. We provide extensive coverage for secondary operations, including ID/OD grinding for parts up to 10” long and surface grinding up to 24”. This capacity allows us to transition seamlessly from small, intricate prototypes to larger production assemblies.

- Turned Diameters to 15-3/4”

- OD Grind (max) 6” Round x 24” Long

- ID Grind (max) 8” Round x 10” Long

- Thread Grind (max) 4” Round x 12” Long

- Surface Grind (max) 12” x 24” x 10”

- Milling (max) 20” x 40” x 25”